Male&Female M/F Threaded Long Bend 90 Elbow Galvanized Fittings

Malleable iron Pipe fittings of Application

Pipe fittings, also known as pipe parts, are a kind of accessories that play a role in connection in the pipeline. There are many types of pipe fittings, and threaded malleable cast iron pipe fittings are used more. This type of pipe is widely used in water and gas pipelines oil and other fluids..

| Product | Long Bend Elbow |

| Material | Malleable Iron |

| Size | 3/8.1/2,3/4,1, 1 1/2, 1 1/4, 2,3,4,5,6,8 inch |

| Standard | BSI,GB,JIS,ASTM,DIN |

| Surface | Cold Galvanized, Deep hot Galvanized. Nature black Sandblast |

| Ends | Thread: BSPT(ISO 7/1),NPT(ASME B16.3) |

| Specification | Elbow Tee Socket coupler Union Bushing Plug |

| Application | steam, air, water, gas, oil and other fluids |

| Certificate | ISO9001-2015, UL, FM, WRAS, CE |

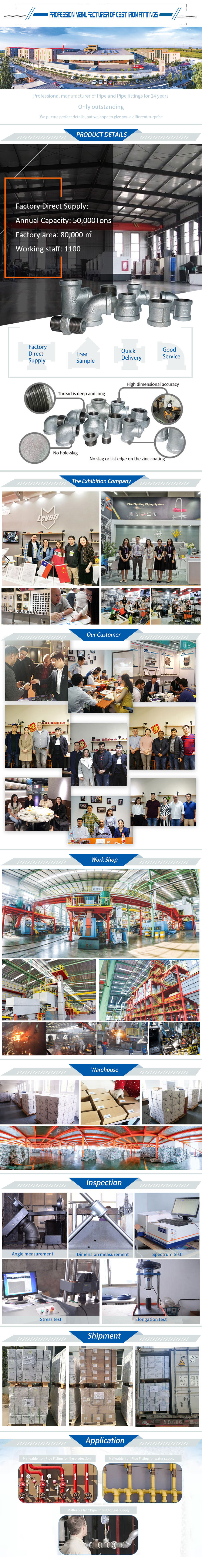

Malleable iron Pipe fittings of Strict Quality Control

1) During and after production, 10 QC staffs with more than 10 years experience inspect products in random.

2) National accredited laboratory with CNAS certificates

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4) Approved UL /FM, ISO9001, CE certificates.

Features of hot-dip galvanized standard parts:

1. Good reliability: The galvanized layer and the steel are metallurgically bonded and become a part of the steel surface, so the durability of the coating is more reliable;

2. Comprehensive protection: every part of the plated parts can be plated with zinc, even in recesses, sharp corners and hidden places can be fully protected;

3. Low processing cost: the cost of hot-dip galvanizing and rust prevention is lower than that of other paint coatings;

4. Time-saving and labor-saving: the galvanizing process is faster than other coating construction methods, and it can avoid the time required for painting on the construction site after installation;

5. Durable and durable: In the suburban environment, the standard hot-dip galvanized anti-rust thickness can be maintained for more than 50 years without repairing; in urban or offshore areas, the standard hot-dip galvanizing anti-rust layer can be maintained for 20 years without repairing ;

6. The coating has strong toughness: the zinc coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.