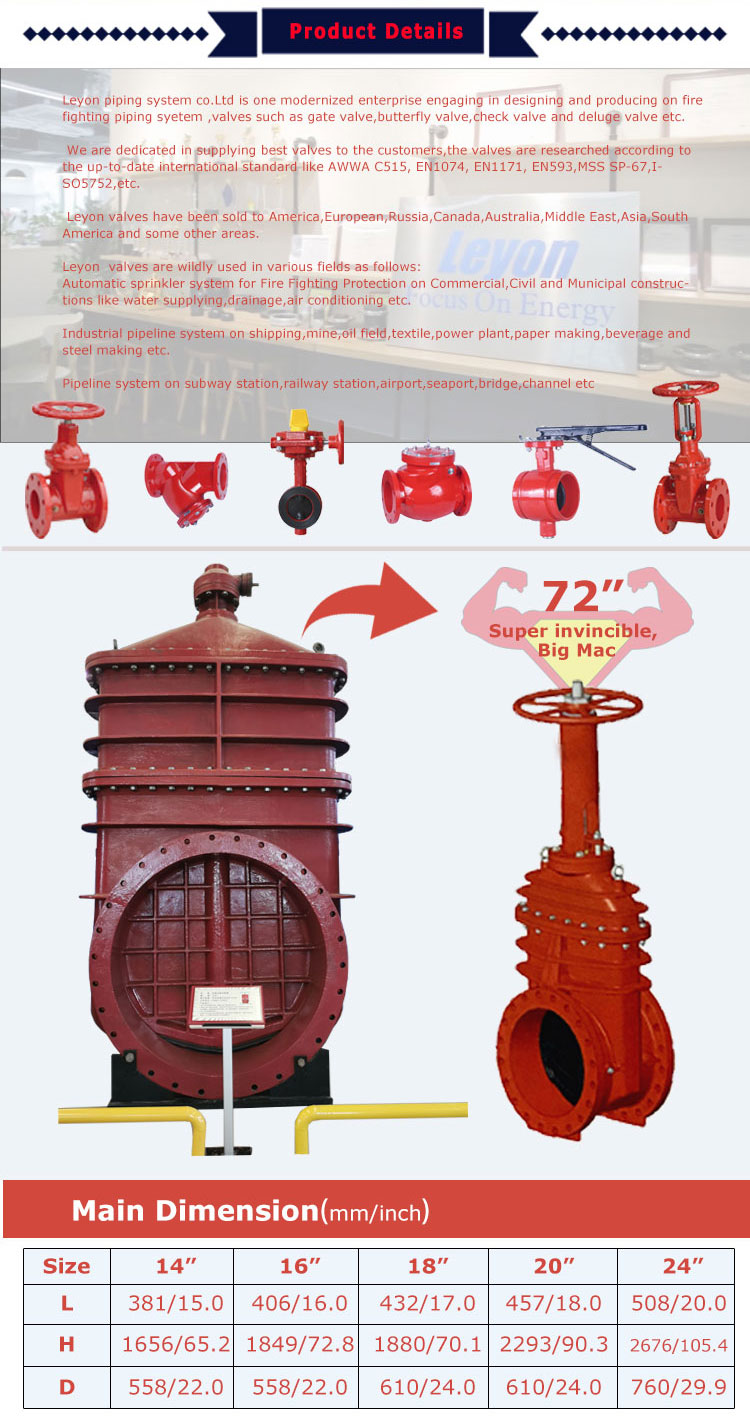

Leyon Fire Fighting Flanged NRS Gate Ductile Iron Resilient Seat Gate Valve

Leyon Flanged NRS Gate Ductile Iron Resilient Seat Gate Valve

Key Components

- Body Material: Ductile Iron

- Description: The valve body is made from ductile iron, a material that offers higher tensile strength, impact resistance, and flexibility compared to traditional cast iron.

- Benefits:

- Superior resistance to mechanical stress and shock.

- Higher pressure and temperature resistance than gray cast iron.

- Better resistance to corrosion when coated (e.g., with epoxy coating) for use in water systems.

- Gate (Disc)

- Description: The gate, often made of ductile iron, is fully encapsulated in a resilient material (commonly EPDM rubber) to provide a bubble-tight seal.

- Benefits:

- The resilient material allows for a tight, leak-proof seal.

- Reduces wear and tear on the sealing surfaces, increasing durability and lifespan.

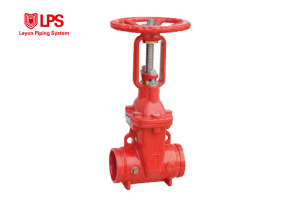

- Non-Rising Stem (NRS)

- Description: Unlike rising stem valves, the stem remains stationary as the gate moves up and down.

- Benefits:

- Space-saving design: Ideal for installations in confined spaces or underground systems where vertical space is limited.

- Protected stem threads: Since the threads are inside the valve body, they are less exposed to dirt, corrosion, and mechanical damage.

- Resilient Seat

- Description: The resilient seat is typically made from rubber (e.g., EPDM), which is molded onto the gate.

- Benefits:

- Provides a tight shutoff without metal-to-metal contact.

- Reduces leakage and offers a longer lifespan due to its resistance to water hammer and fluid pressure surges.

- Bonnet and Sealing System

- Description: The bonnet is typically bolted to the valve body, with a sealing system using O-rings or gaskets to prevent leakage.

- Benefits:

- Easy to disassemble for maintenance and repairs.

- Effective sealing to prevent leaks from the valve body.

- Coating and Corrosion Protection

- Description: Ductile iron valves are typically coated with fusion-bonded epoxy (FBE) or similar coatings to protect against corrosion, especially in potable water systems.

- Benefits:

- Provides superior corrosion resistance.

- Ensures compliance with drinking water safety standards (e.g., NSF/ANSI 61 certification).

Description

This kind of UL FM valve is widely used in the field of fire protection, and it is connected by flange, which is convenient and quick to install. Pressure rated up to 200 psi, 350 psi. The valve is designed for above ground installations, and it is specifically used in fire protection sprinkler systems. A valve stem and nut are mounted on the outside of the valve body for easy identification of whether the valve is in the open or closed position.

Write your message here and send it to us