Leyon Fire Fighting Carbon Steel Pipe Fittings Butt Welded Elbow

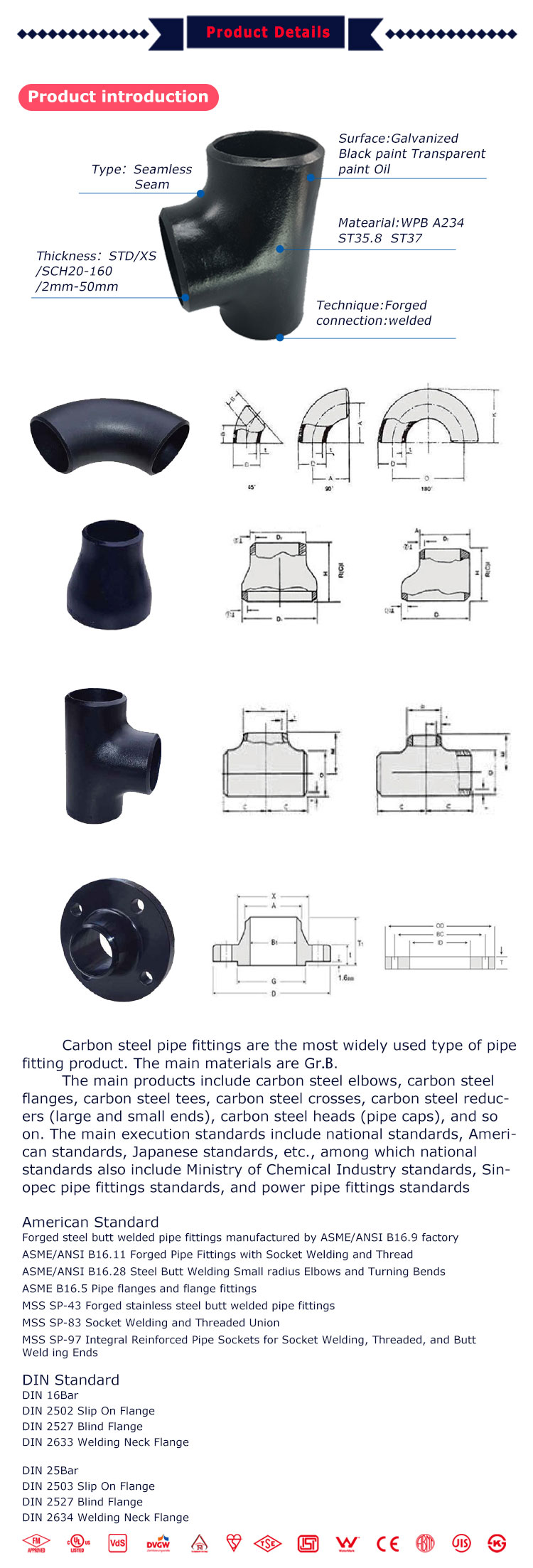

Carbon steel pipe fittings are the most widely used type of pipefitting product. The main materials are Gr.B.The main products include carbon steel elbows, carbon steelflanges, carbon steel tees, carbon steel crosses, carbon steel reduc-ers (large and small ends), carbon steel heads (pipe caps), and soon. The main execution standards include national standards, Ameri-can standards, Japanese standards, etc., among which nationalstandards also include Ministry of Chemical Industry standards, Sin-opec pipe fittings standards, and power pipe fittings standards

American StandardForged steel butt welded pipe fittings manufactured by ASME/ANSI B16.9 factoryASME/ANSI B16.11 Forged Pipe Fittings with Socket Welding and ThreadASME/ANSI B16.28 Steel Butt Welding Small radius Elbows and Turning BendsASME B16.5 Pipe flanges and flange fittingsMSS SP-43 Forged stainless steel butt welded pipe fittingsMSS SP-83 Socket Welding and Threaded UnionMSS SP-97 Integral Reinforced Pipe Sockets for Socket Welding, Threaded, and ButtWeld ing Ends

DIN Standard

DIN 16Bar

DIN 2502 Slip On FlangeDIN 2527 Blind Flange

DIN 2633 Welding Neck Flange

DIN 25Bar

DIN 2503 Slip On Flange

DIN 2527 Blind Flange

DIN 2634 Welding Neck Flange

Butt-welded fittings are used in a piping system for changing direction branching and to mechanically joined to the system. A piping system using Butt-welded fittings has many inherent advantages over other forms. Butt-welded fittings are used widely in high pressure and high temperature application.

Material

Material specification is totally in compliance with ASTM A 234. This standard covers wrought carbon steel fittings of seamless and welded construction which are manufactured to the dimensional specifications of ASME B16.9. These fittings are primarily for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures. The starting material for fitting sconsist of killed (deoxidized) steel, forgings, bars, plates; seamless orfusion-welded tubular products with filler metal added and conform tothe Mechanical & Chemical requirements of ASTM A 234.

Manufacturing Process Forging or shaping operations are performed by hammering, pressing.piercing,extruding, upsetting, rolling.bending,fusion welding or by combination of two or more of these operations.

|

Material

|

ASTM, A234WPB, A234WPC, A420WPL6

|

|

Standard

|

ASTM A234 WPB

|

|

Surfacetreatment

|

Black Paint, Anti Rust Oil, Hot-Dipped Galvanize

|

|

Wall thickness

|

SCH10,SCH40

|

|

Model

|

Elbow, Tee, Flange, Cap, Coupler

|

|

Connection

|

Welding

|

|

Shape

|

Equal, Reducing

|

|

Certificate

|

API

|

|

Application

|

fire fighting piping system

|

|

Delivery Details

|

According to the quantities and specifications of each order

|

|

Normal delivery times is from 30 to 45 days after receiving the deposit

|