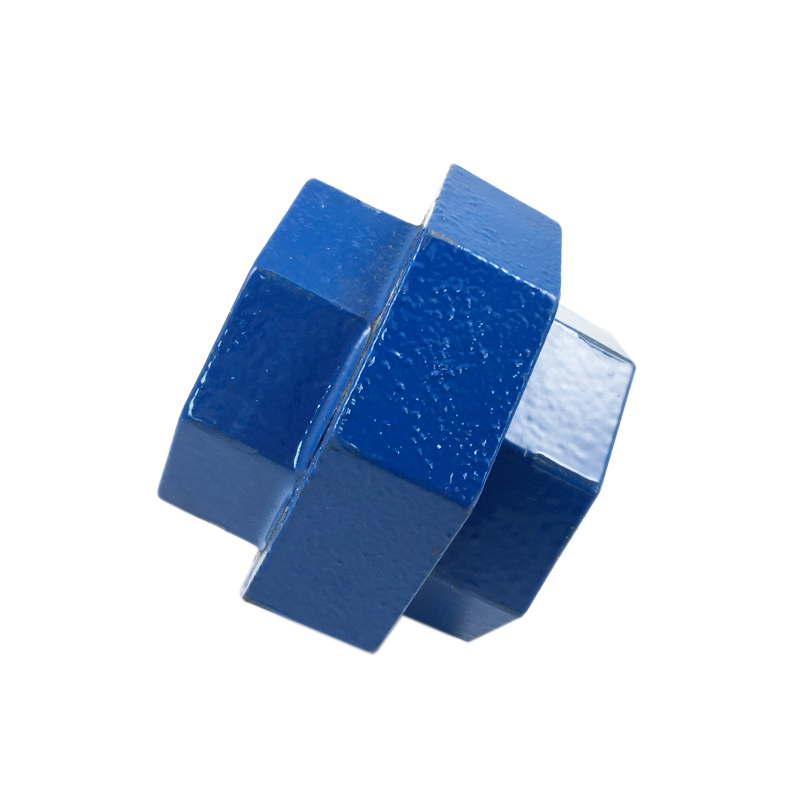

ANSI JIS Standard Ductile Iron Cast Iron Pipe Fitting Union for Fire Fighting

Grooved clamp of description

Leyon Grooved piping system is reliable and is faster to install than welding, threading or flanging, resulting in lowest installed cost. It can be adopted to suit standard pipe with cut grooves or standard and light wall pipe with rolled grooves. Couplings perform equally well under pressure and vacuum. Couplings are available for flexible and rigid system. Grooved end fitting are machined to AWWA C606 cut groove standard Products are offered with RAL 3000 alkyl enamel rust preventive paint as standard and hot dipped galvanized coating is available optionally.

Grooved clamp of featured

1.AWWA size fittings are supplied with rigid radius grooves in accordance with ANSI/AWWA C-606

2.Fittings conform to ANSI 21.10/AWWA C-110 for center-to-end dimensions and AWWA C-153 or ANSI 21.10/AWWA C-110 for wall thicknesses

3.Available with a wide variety of coatings and linings

4.Victaulic can supply tapped fittings that meet ANSI B16.1 dimension locations

5.Sizes from 3 – 36″ | DN80 – DN900

6.Pressure rated up to 350 psi | 2413 kPa | 24 bar

Grooved clamp of application

Today grooved couplings along with grooved fittings, grooved valves and grooved accessories (such as strainers and suction diffusers) are found in a seemingly endless number of piping applications worldwide.

While the grooved pipe joining concept has become synonymous with faster and easier installations, not all manufacturers of grooved products are the same. There is reliable, durable, precision-constructed piping systems.

| Product | Ductile iron Grooved pipe fittings |

| Material | Ductile iron |

| Size | 4 in to 36 inch |

| Standard | BSI,GB,JIS,ASTM,DIN,AWWA |

| Surface | Hot Dip Galvanized. RAL3000 paint |

| Ends | Threaded, Outlet , Grooved |

| Component | Gasket Housings Nuts and bolts |

| Specification | Elbow Tee Flexible coupler Cap Rigid Coupler |

| Application | Fire protection system |

| Certificate | ISO9001-2015, UL, FM, WRAS, CE |

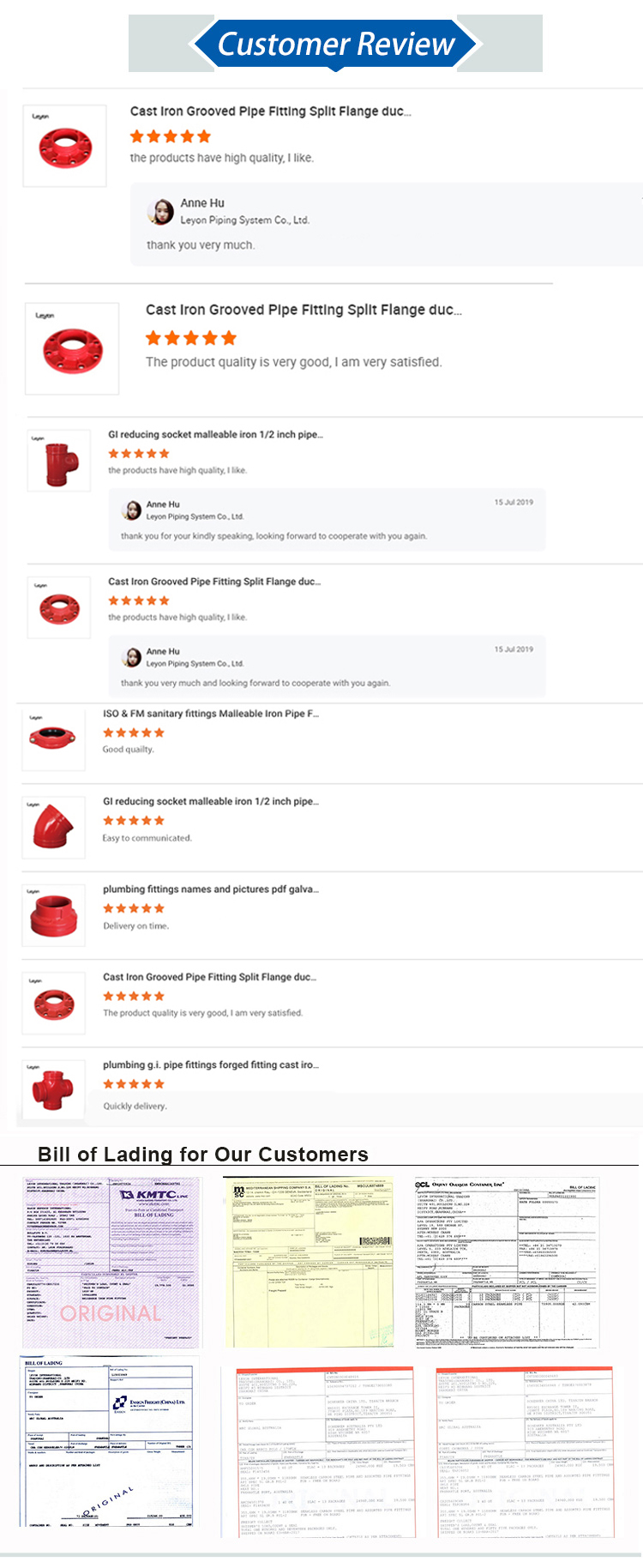

Strict Quality Control

1.During and after production, 10 QC staffs with more than 10 years experience inspect products in random.

2.National accredited laboratory with CNAS certificates

3.Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4.Approved UL /FM, ISO9001, CE certificates.

Professional manufacturer of Pipe and Pipe fittings for 24 year

Only outstanding. We pursue perfect details, but we hope to give you a different

.jpg)